As you may already know, we’ve been doubling down on our efforts in 2024. We’re working hard to increase capacity, elevate quality and meet our ambitious sales target for the year.

Key elements of this hard work include our relocation to larger premises and our continued investment in quality digital printing machinery – machinery that we know will be capable of keeping pace with the ever-evolving product packaging and labelling industry.

In honour of all our hard work, we thought the time had come to take some of our valued customers and collaborators behind the scenes. And we’re so glad we did…

Showcasing our factory and workflow

As we’ve mentioned briefly already, the very first (but certainly not the last!) Kingfisher Labels Open Day event welcomed over 100 curious visitors into our brand-new, 22,000-square-foot hub of operations in Yate.

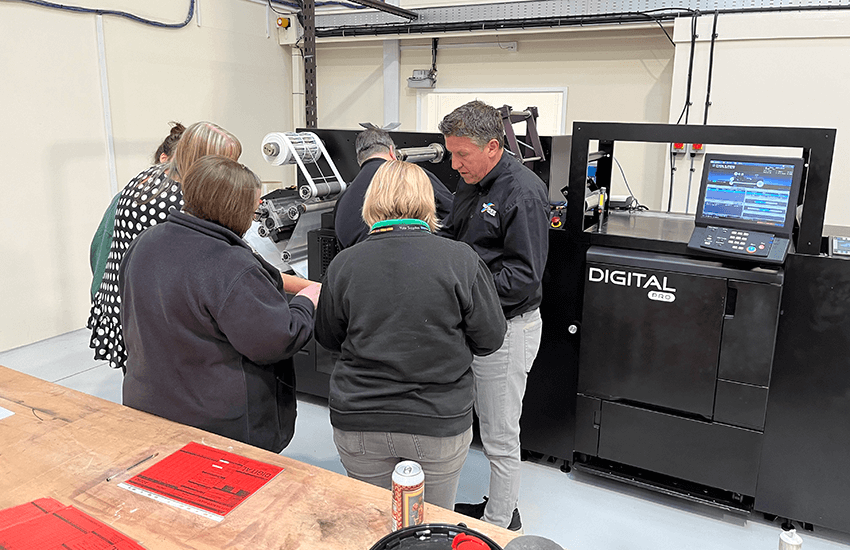

It was wonderful to tour the factory with the team, share some of our secrets, and showcase recent investments in flexographic and digital printing technology, like the Mark Andy Pro 3.

As per our Director, Karl Jackson:

“We have invested heavily in the new premises and latest flexo and digital technology and it’s really paying dividends. […]

Having digital capability rounds out our offering and shows we have grown into a good size business that can offer a full service on jobs from very short to very long, and all with a great deal of customer care.”

The Kingfisher team was also able to evidence an ever-improving, efficiency-focused workflow. On this topic, Karl said:

“We were delighted with the number of our valued customers and suppliers that attended and the positive comments they made about our organisation and production workflow. […]

We work hard to reduce waste to a minimum, especially with expensive substrates, but the costs of sustainability are still more than most customers can afford to pay in today’s price-conscious market.

That’s where the production efficiency of our new facility comes into its own, and we are grateful that so many took the time to come to see it in action.”

Overall, it was a great event – and a happily seized chance to reaffirm our commitment to customer-first, bespoke labelling solutions.

Collaboration, innovation and efficiency

Our provision of high-quality self-adhesive labels remains centred around customer care and transparency.

Even as we expand and reach new sales goals, we understand that priority number one should always be ensuring customer satisfaction, whether that be with the price of a print run, the final product or the support offered along the way.

If you’d like to benefit from our ongoing commitment to meeting customer needs – and create some durable, beautiful labels that help your brand stand out – please contact us to discuss your needs.